[video_player file=”https://simplesolutionsgy.com/wp-content/uploads/2024/05/05-WT8A-Bender.mp4″]

Automatic Rebar Bending Machine - RB25

GYD $720,000

Model LH 500 Concrete Pavement Vibrating Level Ruler

GYD $320,000

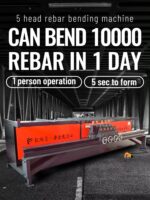

Model WT 8 – A: Five-Head Automatic Rebar Bending & Stirrup Making Machine.

GYD $3,800,000

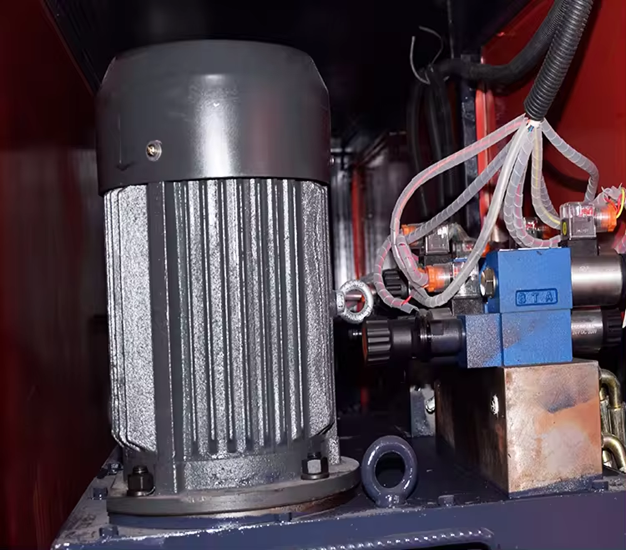

– Hydraulic Pressure: – 15 Mpa Max;

– Forming Speed: – 8 to 10 seconds;

– Operating Temperature: – 60 degrees Celsus;

– Number of Steel Processing Shapes: – 12 shapes;

10

People watching this product now!

Description

Delivery

WE DELIVER

We deliver from East Corentyne to Charity and along the Soesdyke-Linden Highway up to Mackenzie. If you are outside of these areas, please contact us.

Related products

Automatic Rebar Bending Machine – RB25

Rated 0 out of 5

GYD $720,000

- Can bend between 6 to 25 mm diameter rebars (1/4 to 1 inch).

- Bending angle of 0 to 180 degrees, and can reset 2 different angles on the same pass.

- Bending Speed of 5 to 10 seconds using two, foot pedals.

- Durable Single Phase 220 Volts, 60 Cycle motor, no load power 1,700 Watts.

- This machine is suitable for a high productivity environment in medium and large

construction projects. It significantly reduces labour cost and can pay for itself within

one week in labour savings. It advances rebar bending lead time for maintain project

schedule, reduce construction cost, and increase profitability.

Binding Wire Reel – 110m

Rated 0 out of 5

GYD $1,080 Original price was: $1,080.$750Current price is: $750.

Hydraulic/Electric Rebar Cutter RC-16

Rated 0 out of 5

GYD $189,000

Simple Solutions introduces the RC16 Hydraulic/Electric Rebar Cutter machine.

Stop cutting Steel Rods using the inefficient Chop-Saw, and Angle Grinder. These tools have caused severe injuries to many, are very inefficient, and expensive to operate.

It is 220 - 230 Volts, 50/60 Hz, 900 watts, 3-pin plugs.

This machine has received EU certification – certificate No: M. 2018.201.N7865.

It is operated by one worker, is lightweight, reduces stress, rugged, and weighs 13 Kilograms.

It is powered by an electrical motor, and hydraulic shear, using Molybdenum Vanadium Double Sided Cutting Blade.

It can be used to cut steel rods for making mattings and cages, as well as portable enough to work onsite between steel works.

It can cut between 4 to 16 mm corrugated rebar at a speed of 3 to 5 seconds.

The benefits are less fatigue, significant increase in productivity, lower operation cost, no replaceable discs, and easy to operate.